17

LEGS PER WELL

PROTECTED GAUGE

AGGRESSIVE LAYOUT

OVERVIEW

Performance Driven, Canadian Made

Ulterra created the Heavy Oil Gauge (HOG) style of PDC bit to tackle the harsh conditions and unique make-up of drilling in Canada’s heavy oil sands. We engineer our HOG series of bits specifically to handle the challenges presented by this multi-leg, highly abrasive, lateral application. HOG bits feature technology to achieve high ROP while maintaining durability, steerability, and backreaming capability.

About Canada’s Heavy Oil Sands

The Canadian heavy oil sands are the third-largest oil deposit globally and hold 96% of the oil reserves found in Canada. Access to the 165 billion barrels of oil they contain requires drilling multiple legs of long horizontal sections in extremely abrasive sands. This kind of drilling can heavily erode standard drill bit cutting structures and gauge pads, leading to bit body damage and poor steerability.

DRILLING

Optimized for Multi-Leg Laterals

Ulterra’s HOG series of steel PDC bits perform under the harshest conditions. Made in Canada, our heavy oil bits drill as many as 15 legs from one parent casing versus a competitor average of four legs per drill bit. HOG bits clock over 6,000 metres each and significantly reduce trips through excellent durability, steerability, and backreaming capability.

TECHNOLOGY

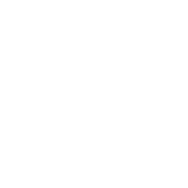

Durability, Steerability, and Backreaming

HOG series bits feature a suite of improvements in the tool face and gauge of the bit. We start with premium OMEGA® abrasion-resistant cutters supported by enhanced hydraulics. But the magic is in the gauge pads, which are heavily fortified with thermally stable diamond elements to maximize borehole quality while maintaining trouble-free backreaming capability. These bits drill clean and precise wellbores that reduce drilling costs and assure a successful completion for a productive well that lasts for years.

Improved Gauge Durability

Ulterra designs large TSP diamonds and in-gauge PDC cutters into our gauge pad to provide extra protection in abrasive applications. Special bit body geometry supporting PDC cutters creates a very effective backreaming feature that allows for easy rotation out of the hole without sticking.

Enhanced Steerability

This heavy oil bit has a unique ability to steer, enabling it to complete an open hole sidetrack and start a new leg without difficulty.

Robust Backreaming

With wellbore quality and operational safety also high considerations, HOG Series bits feature additional protection while backreaming to get through sloughing wellbores that at times can be as great a challenge as drilling.

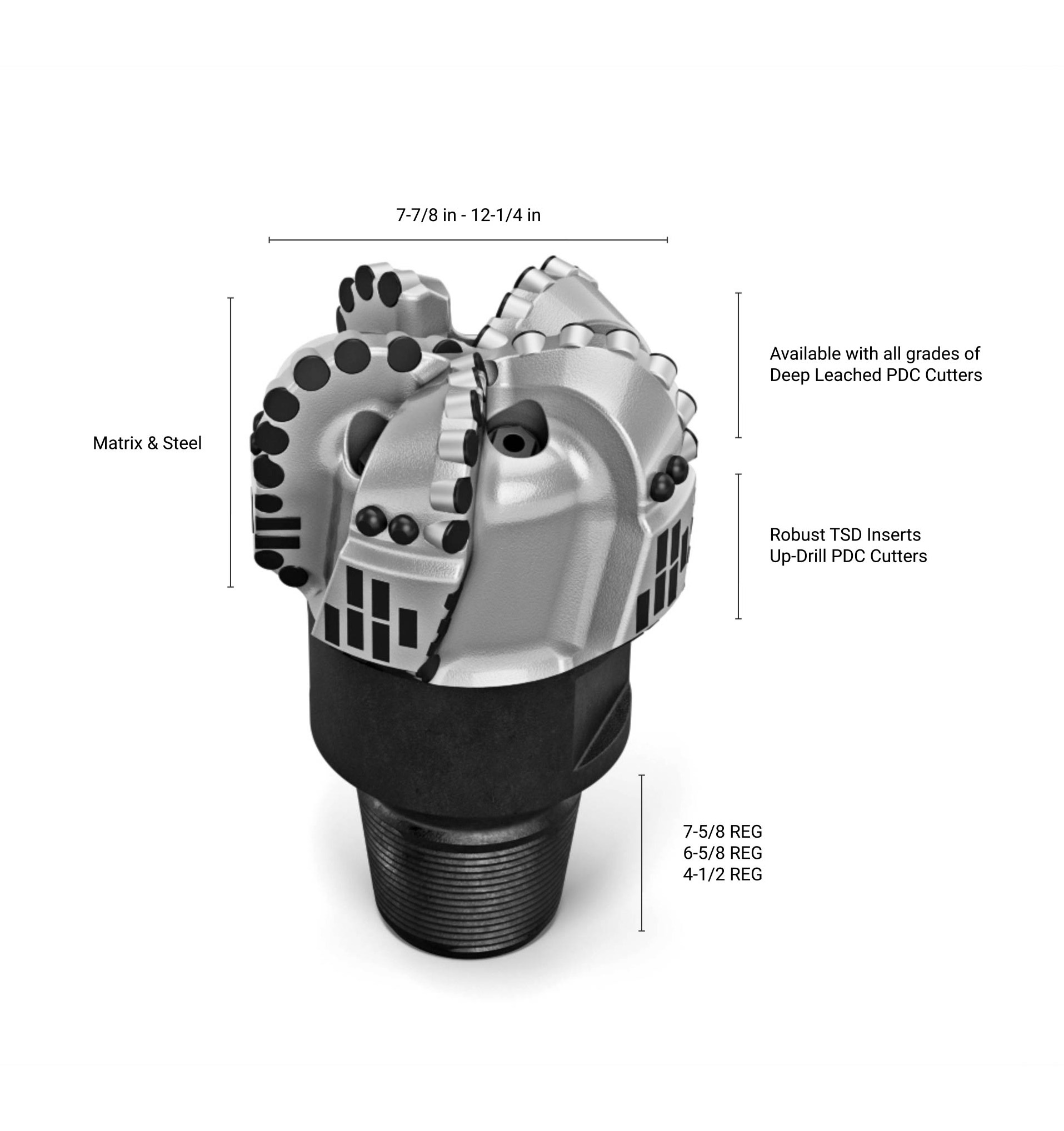

TECHNICAL SPECIFICATIONS

Size Range

12.25 in, 10.625 in, 8.75 in, 7.875 in

Body Materials

Matrix & Steel

Cutter Grades

OMEGA™ Deep Leach Abrasion Cutters

Connections

API Reg or NC

PERFORMANCE

More Lateral Legs in Less Time

In a recent offset covering a pad with 15 legs of a 7-7/8-inch hole, Ulterra HOG bits drilled a 37.5% faster ROP. The configuration was one BHA and one HOG bit, with no bit trips to the surface, vs. a competitor average of five legs from a similar casing set.