SMOOTHER TORQUE

MORE CONTROL

OVERVIEW

Cruise control for changing formations

RipSaw from Ulterra is the PDC bit that keeps you drilling smoothly through changing conditions, limiting torque spikes while delivering consistent engagement that improve performance and maintain ROP. This is especially difficult to achieve in drilling environments with high interfacial severity between formations. Ulterra engineers devised our award-winning Ripsaw technology to anticipate and resist sudden changes in rock properties and adapt the depth of cut (DOC) to the reactive torque that follows. The Active Torque Technology, Ripsaw’s cutting structure, brings new meaning for increasing stability and reliability in challenging drilling conditions.

DRILLING

Depth of Cut Un-limited

Many applications involve drilling through formation transitions that have high degrees of change in the compressive strength of the rock. Not just between formations tops, but interbedded formations as well. This means additional protection is often required, typically in the form of depth of cut control. Traditional solutions that address depth of cut control are flawed in some way, as they either directly restrict performance in the fast formations or compromise the bit design with added complexity. RipSaw is a depth of cut control solution without compromise; capable of demonstrating superior stability and durability when drilling through changing formations or extended reach lateral sections.

Ulterra’s RipSaw technology is proven to get your drillers to TD faster when going through changing formations.

TECHNOLOGY

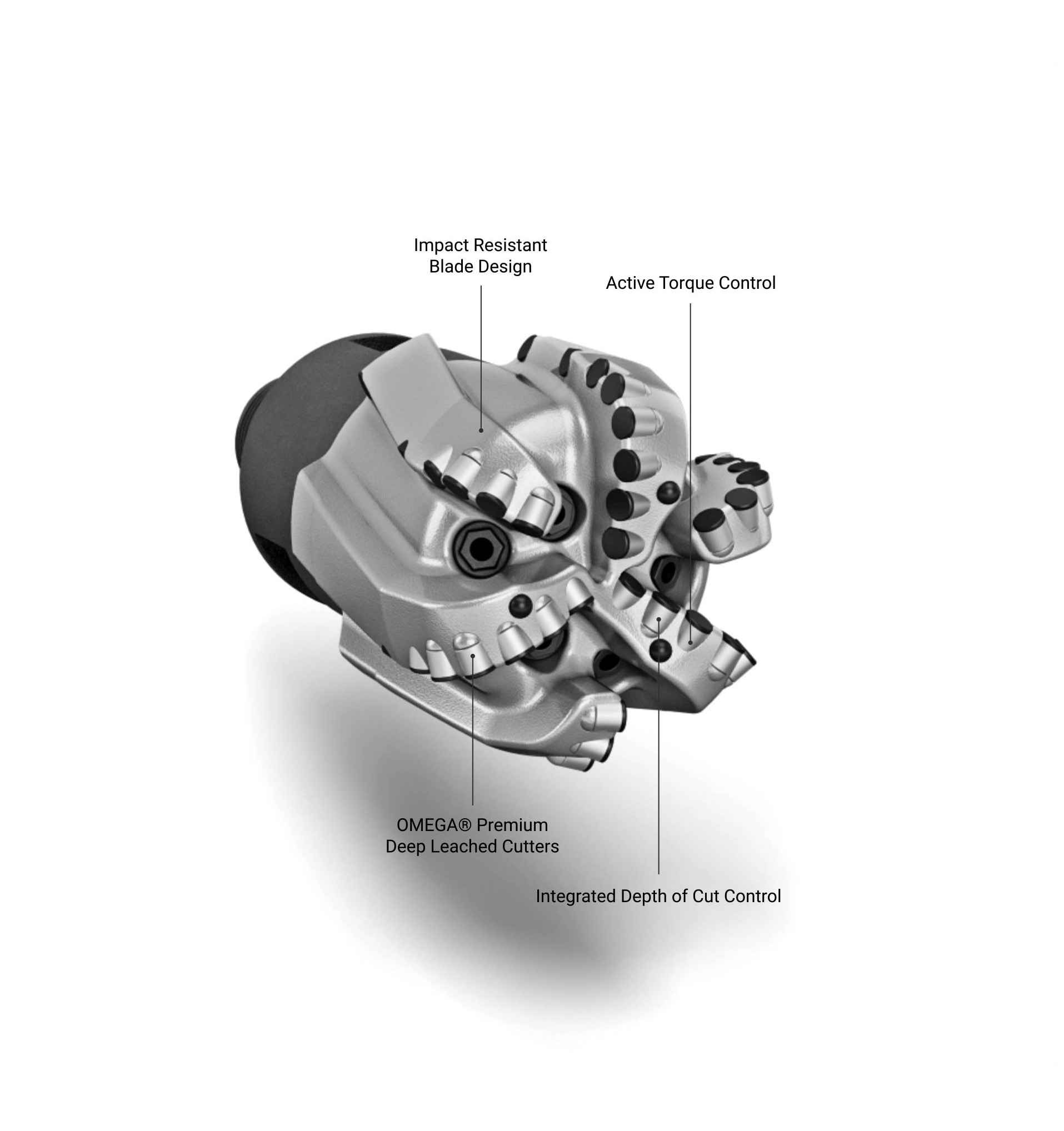

Active Torque Technology Controls Changing Formations

Active Torque means that the solution is active across the drill bit’s entire range of depth of cut and part of the cutting structure that is actively engaged in drilling. Rather than using under-exposed and underwhelming secondary elements, RipSaw uses cutting elements which are always actively engaged. With cutter backrakes poised to deliver a more manageable torque response, drillers experience better feel and feedback across the entire operating range of the bit, with superior reliability.

- Instantaneous, active damping of drilling forces

- Active depth of cut control across the bits’ entire operating range

- No hard stop fixed elements which limit ROP

- No moving parts, no additional risk

TECHNICAL SPECIFICATIONS

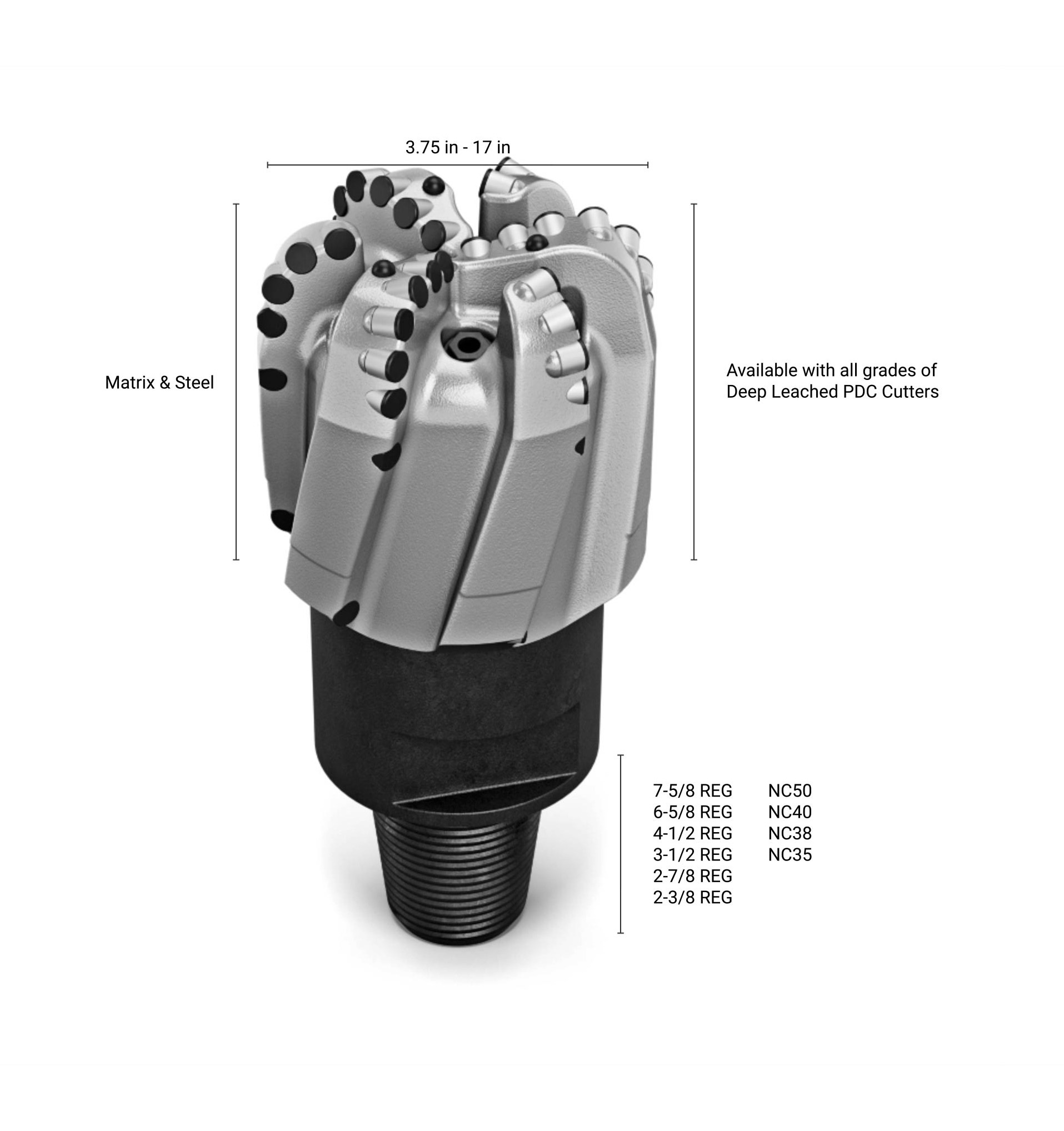

Size Range

3.75 in – 17 in

Body Materials

Matrix & Steel

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

3-1/2 REG, 4-1/2 REG, 6-7/8 REG, 7-7/8 REG

NC35, NC38, NC40, NC50

APPLICATIONS

Wherever Control Is Critical, Use RipSaw™

RipSaw’s Active Torque Technology works wherever you need control of depth of cut, drilling torque, or toolface. Since this applies to many different drilling applications, it means that RipSaw will bring an advantage almost anywhere that it is applied.

Transitional Drilling

Many well sections pass through layers of soft-hard-soft transitions, and constantly changing rock properties cause severe torque and depth of cut issues. These intervals of high interfacial severity can result in damage to bits and down hole tools.

Curves and Complex Directional Sections

Where precise directional work is necessary, managing torque is critical to controlling tool face. Failure to do so can lead to missed targets and zones.

Deep and Extended Reach Well Profiles

In deep wells and long laterals, weight transfer issues lead to inconsistent depth of cut, making it difficult to drill ahead. In each case, a consistent solution to smoothing torque response across a wide range of parameters is worth hundreds of thousands of dollars in cost savings.

PERFORMANCE

Vibration Turned into Speed

Rather than simply limiting bit performance with secondary features, Ulterra engineers devised a better way. RipSaw engages changing rock properties and drilling parameters that smooth torque oscillations with the active cutting structure. In addition, RipSaw’s unique blade design and superior hydraulics significantly improve cuttings evacuation and prevent recirculation for better performance and ROP.

RipSaw regulates cutting forces, redirecting and absorbing force to increase stability. The bit’s technology works like a shock absorber, enabling movement and high engagement but protecting against damaging shock and impact. Ulterra’s engineers used highly-engineered cutter positioning on different parts of the cutting structure to create RipSaw’s outstanding durability.