INCREASE ROP

HIGHER TOUGHNESS

OVERVIEW

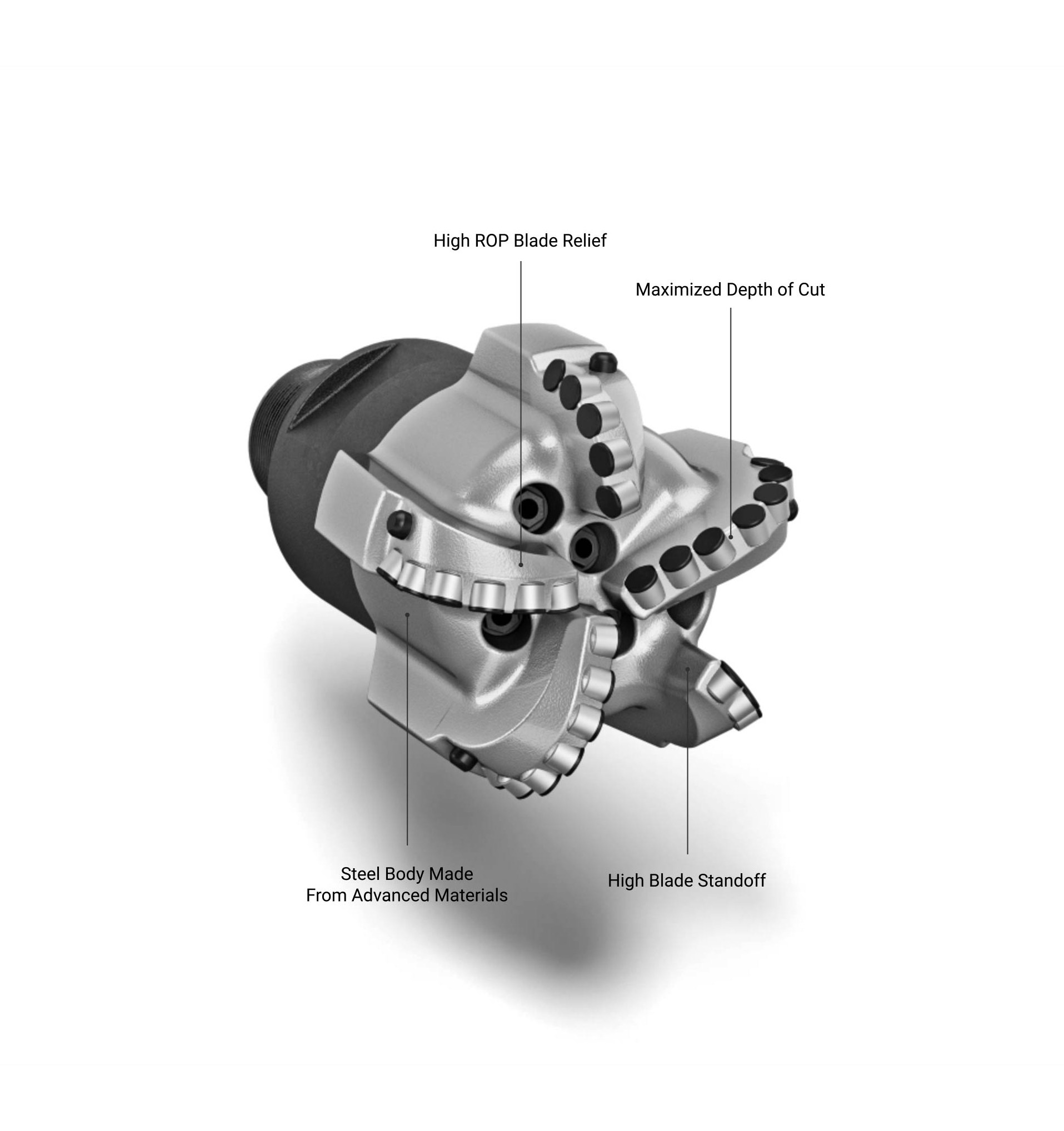

Strong, Durable FastBack

Tungsten carbide, diamond, unique alloys, and high-tensile treated steel. PDC bits are made up of some of the most extreme materials on the planet. However, radical properties often require significant design and manufacturing trade-offs that affect performance.

Ulterra decided to change the game and set themselves the challenge of creating a PDC platform that was superior to both traditional matrix and steel-bodied PDC bits. Instead of limiting PDC bits by the weakness of the materials, FastBack aligns their strengths so each part of the construction enhances the others.

It’s not just the features you can see; it’s the manufacturing processes, quality standards, and material properties that make a FastBack bit the best in the industry.

MAXIMIZE ROP

Blades Shaped for Efficiency

Today’s drilling environment is focused on higher parameters and increased efficiency by eliminating factors that get in the way of increased performance. Traditional PDC blade geometry uses wide blades that drag on the formation under high ROP and high WOB situations, prematurely hitting the founder point and placing a barrier to performance.

With FastBack, we get the blade out of the way and bury the cutters deep into the formation. Because FastBack bits are built with superior materials and engineering principles, we can design the bit in a way that focuses more of the drilling energy on the PDC cutters. The most obvious visual effect of this is the tall, thin, sculpted blades of a FastBack bit, a feature that is only possible through the use of the most advanced materials technology in the business.

- Mechanically supports the PDC cutters in a minimalist fashion

- All energy focused on sharp, diamond-cutting surfaces

- No energy wasted pushing flat blade surfaces into the formation

TECHNOLOGY

Superior Materials, Superior Shape

FastBack’s performance only increases as parameters rise into the higher WOB ranges. By using world-leading materials and engineering technology, Ulterra has designed a drill bit that is capable of reaching beyond traditional performance limits. In fact, the faster we drill, the more cuttings need to be evacuated from the bit face to avoid foundering simply from cuttings build-up. A multi-faceted solution, FastBack technology allows for thinner blades with higher blade standoff without sacrificing strength. This, in turn, opens the face volume of the bit, freeing mudflow, and allowing for higher hydraulic efficiency with better cutting evacuation.

FastBack combines materials to bring you the toughest and most erosion-resistant bit possible.

Built-in toughness

structural steel body material is up to 4x stronger than conventional blades

Maximum erosion resistance

super-hard surfacing materials are selectively placed to deliver better erosion-resistant properties

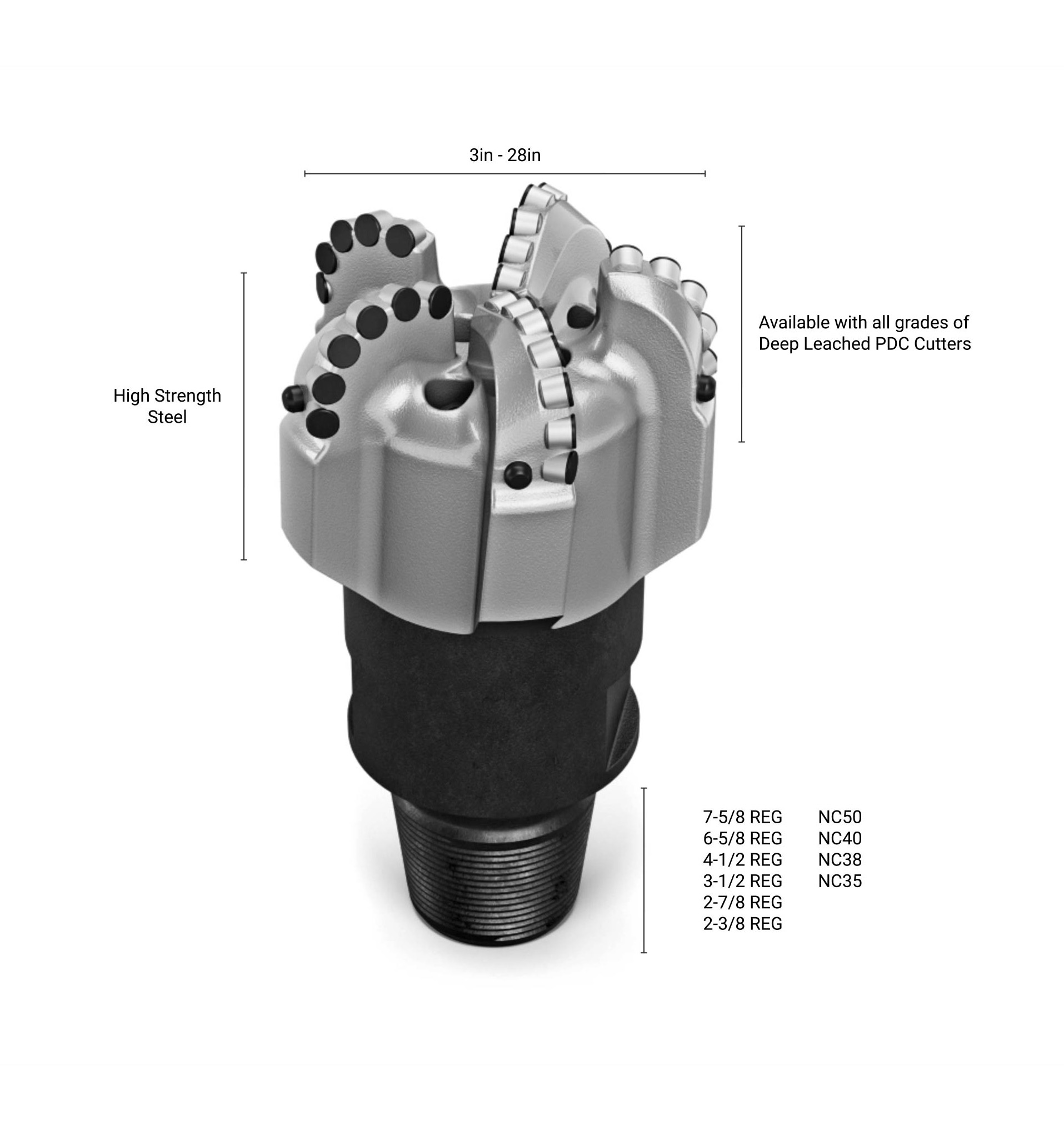

TECHNICAL SPECIFICATIONS

Size Range

3 in – 28 in

Body Materials

Steel

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

2-3/8 REG, 2-7/8 REG, 3-1/2 REG, 4-1/2 REG, 6-7/8 REG, 7-7/8 REG

NC35, NC38, NC40, NC50

APPLICATIONS

Breaking thru ROP Barriers

Fastback technology has been applied in every major basin to gain a performance edge. Fastback works in vertical, curve, and lateral applications. When you need to break thru your performance ceiling and find extra rate of penetration, FastBack technology has set new performance records from the Permian, to the Eagle Ford, and the fields of Oman by removing physical limitation to depth of cut and ROP slope limitation.

PERFORMANCE

When Speed is Paramount

FastBack provides powerful benefits in applications that demand the highest-performing bit technology:

- Superior materials provide increased strength and toughness with erosion and abrasion resistance.

- Focuses energy into the sharp, diamond-cutter edge to drill more efficiently.

- Wide-open blade structure provides optimal hydraulics.

- Quality-focused design and manufacturing process ensures industry-leading reliability.

- Optimal use of materials delivers performance.