AIR -TO- MUD TRANSITIONAL

LONGER LASTING

HIGHER ROP

OVERVIEW

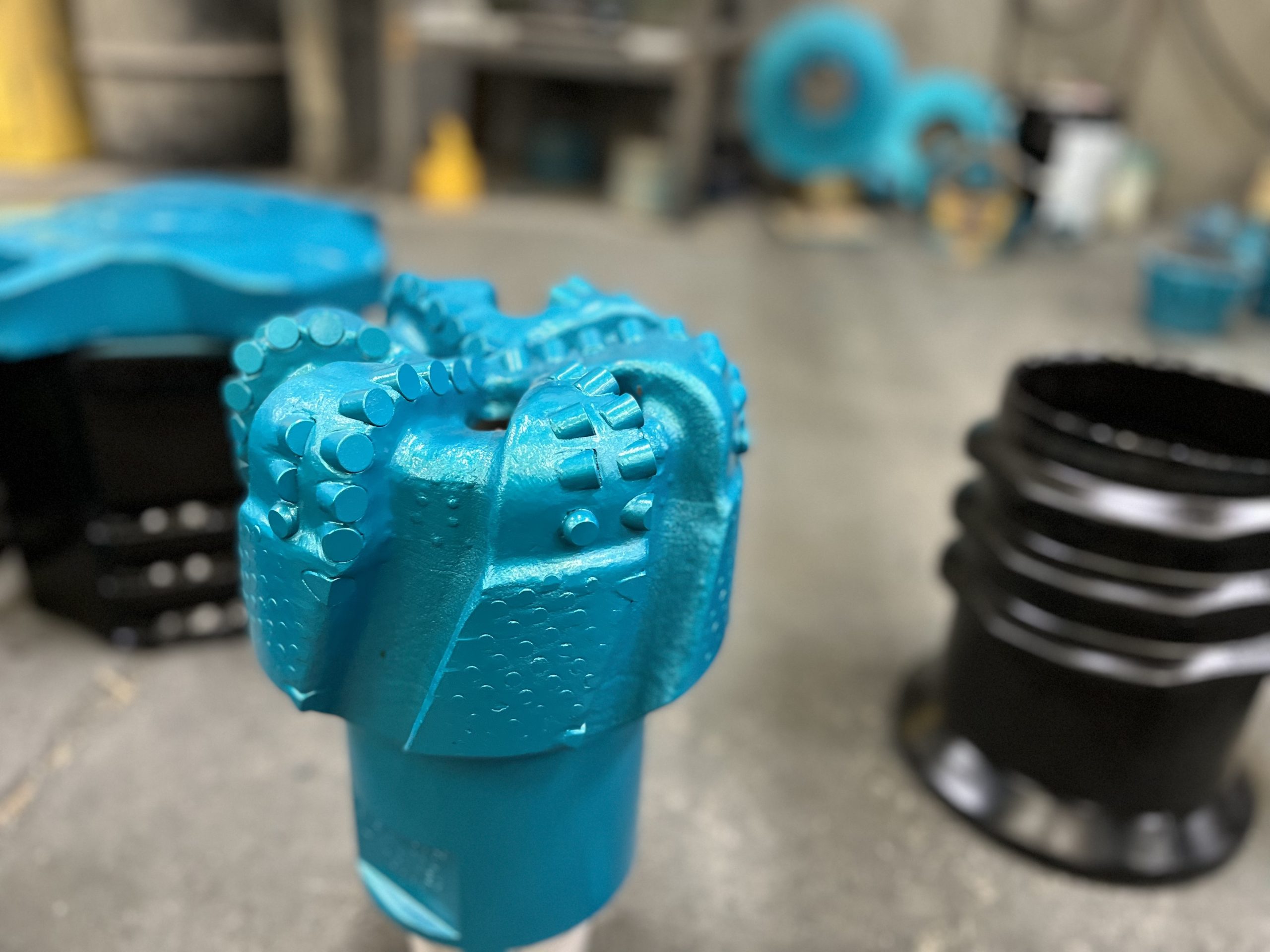

The Power of PDC on Air

AirRaid® is the newest industry innovation bringing the performance and consistency of PDC bits to air drilling applications. For the forward-thinking oilfield professionals drilling air intervals, AirRaid is the first and only PDC drill bit that offers the most in durability and toughness for air drilling applications. AirRaid makes AirPDC® possible, and this new class of bit is specially engineered to control airflow to maintain integrity throughout the interval. As a result, this revolutionary new bit drills faster than roller cones without the moving parts.

AirRaid is engineered for maximum performance in environments with a significant decrease in hydrostatic pressure over common mud-type systems for increased ROP, and the high air velocities used to drill wells provide for improved hole cleaning. There are no chemicals to absorb and no cuttings cleaning requirements on new formations, resulting in lower mud and cuttings handling costs.

Get these AirRaid advantages:

- PDC Technology on Air

- Deep-Leached Cutters

- PDC Bit Bodies

- Clean Hydraulics

PDC PERFORMANCE

Maximum Durability with Increased ROP

Air drilling technology is considered to be a cost-effective drilling method for operators – requiring minimal cleanup and disposal of fluid on the surface. Often, operators drill down to the tangent/curve on air, trip out for a curve assembly, and drill the rest of the curve with drilling mud. This process highlights that air drilling is faster, but it can only go so far before operators are forced to switch gears and run a mud based BHA.

With Ulterra’s AirRaid, operators can finally mud-up their BHA at any time, without tripping out, to finish drilling the entire section and save valuable hours of rig time. Not only are AirRaid bits suitable for operation on mud or air, but they deliver performance and durability that meets and exceeds respective benchmarks as well. With AirRaid, operators can drill vertical, tangent, and curve sections without losing time to trips or poor performance from having the wrong bit in the wrong part of the hole. Leading to higher consistency, better performance over time, and greater cost savings.

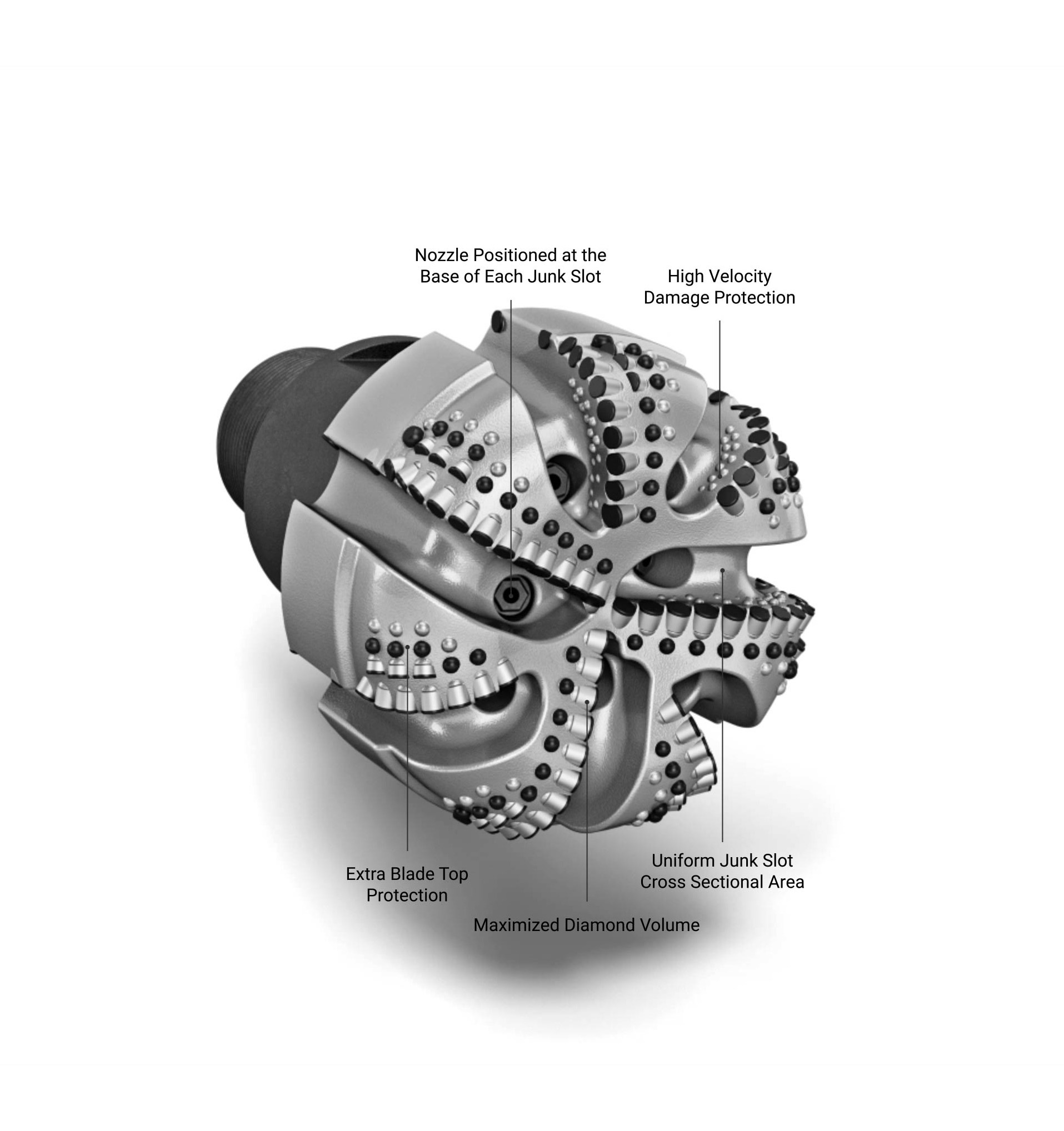

- Mechanically supports the PDC cutters in a minimalist fashion.

- All energy focused on sharp, diamond-cutting surfaces.

- No energy wasted pushing flat blade surfaces into the formation.

TECHNOLOGY

Bringing Performance and Consistency to Air Drilling

AirRaid by Ulterra provides value-added drilling performance and lower rig costs by solving the challenges of air drilling with PDC technology. The superior airflow control effectively cools the drill bit and lifts cuttings out of the wellbore, without the conventional use of liquids. The result for operators is faster drilling and improved ROP, while helping eliminate lost circulation problems.

For air drilling environments, AirRaid unleashes the cutting power of air bits with the performance power of PDC. Ulterra has engineered AirRaid to meet the demands of the toughest air drilling applications with minimal wear and tear. This innovative durability means operators can continue pushing the boundaries of performance without the limitations of standard roller cones.

Greater ROP Potential

Revolutionary design provides for greater ROP potential compared to roller cone bits, so operators never risk downtime or performance limitations.

Improved Tool Face Control

Successfully meets the challenges of drilling directionally at improved ROP — with enhanced PDC tool face control and speed.

High-Strength Quality

Greater dull grade results in less damage to the bit body and cutter substrates, in addition to improving borehole quality over roller cones.

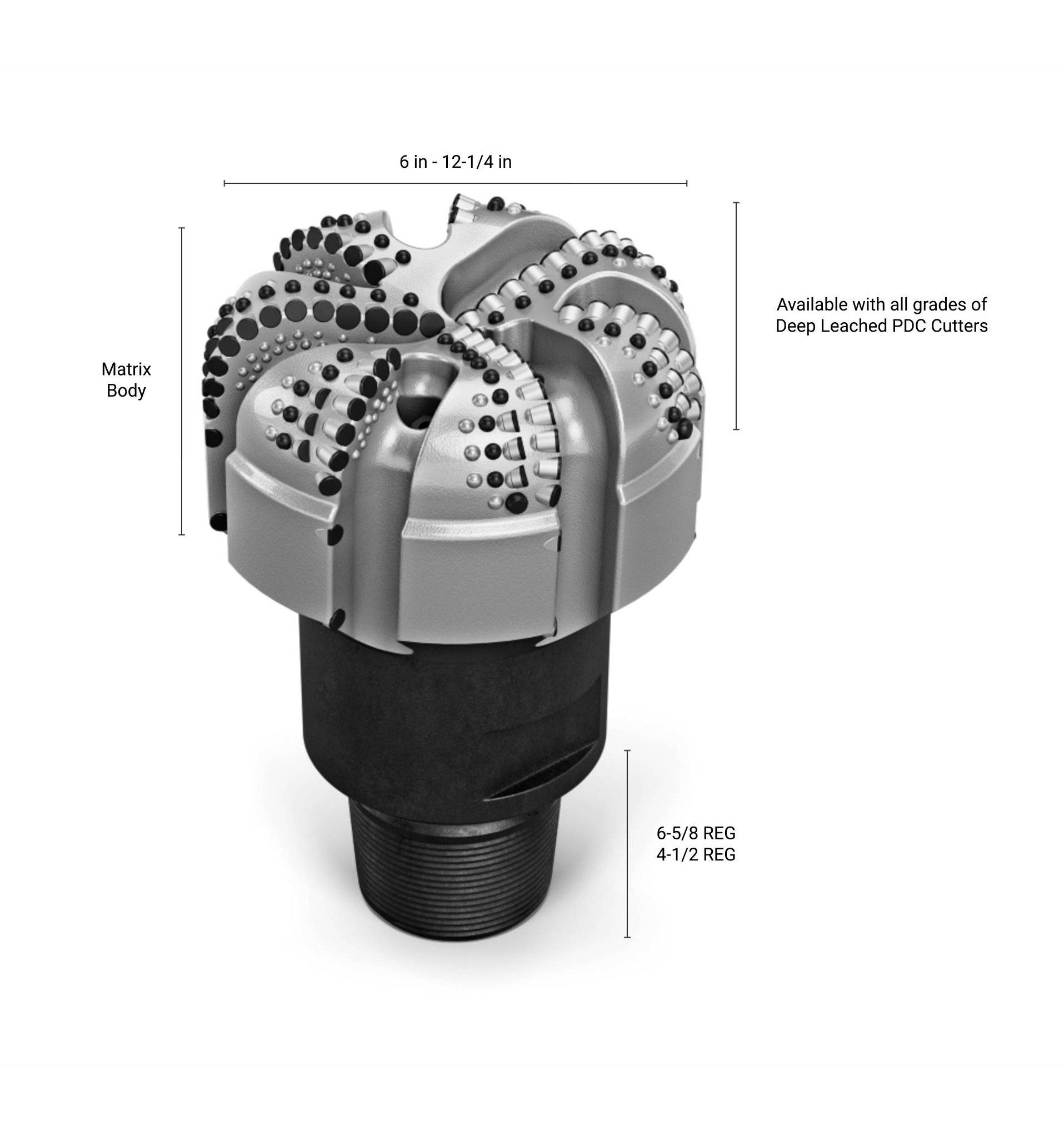

TECHNICAL SPECIFICATIONS

Size Range

6 in – 12-1/4 in (other sizes available upon request)

Body Materials

Matrix Body

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

4-1/2 REG, 6-5/8 REG

Available Features

Load Limiters

Casing Drill Out

Double Row PDCs

Extended Gauge Pad Length

Shortened Gauge Pad Length

Fixed Ports

In-Gauge PDCs

Up-Drill PDCs

Bit Styles

AIR613

AIR713

AIR813

PERFORMANCE

Revolutionizing Air Technology

AirRaid can withstand the most challenging air drilling environments with minimal damage. The bit body geometry controls and harnesses the multiphase air-based fluid to reduce high-velocity vortices. This drastically improves the overall life of the bit for longer-lasting operation and dependability. We developed the design using advanced Computational Fluid Dynamics (CFD) software to ensure optimal capabilities throughout various air drilling applications.

Air drilling technology is widely considered the least expensive fluid for operators – requiring no cleanup or disposal of fluid on the surface – and drills up to 4X faster than conventional systems. With AirRaid, the minimal drilling time, reduced drilling fluid costs, and low cuttings handling expenses provide a smarter and longer-lasting PDC bit solution that revolutionizes air drilling operations.