REDUCE VIBRATION

FASTER ROP

OVERVIEW

The Benchmark in PDC Bit Technology

CounterForce from Ulterra was developed to combat drilling dysfunction caused by systemic lateral vibration. Counterforce PDC bits are field-proven across over 20 basins globally, with records set in every interval and collectively drilling 50 million feet of hole every year! With Ulterra’s patented CounterForce technology, operators take back control of their BHA from the harmful effects of vibration and find new levels of performance.

- Convert vibrational energy into performance

- Improve ROP with better efficiency

- Drill smoother, less tortuous wellbores

- Reduce costs by drilling more footage per bit

WORLD OIL AWARDS

BEST DRILLING TECHNOLOGY 2013

LAGCOE TECHNOLOGY SHOWCASE 2014

WORLD OIL AWARDS

BEST DRILLING TECHNOLOGY 2013

LAGCOE TECHNOLOGY SHOWCASE 2014

VIBRATION

Harness the Energy of Lateral Vibration

Downhole drilling vibration caused by bit-to-formation engagement is the root cause of multiple common drilling issues that can damage drilling tools and equipment. Specifically, lateral vibration is detrimental to the integrity of traditional cutting structures in most drill bits, regardless of the cutters used.

Ulterra’s CounterForce technology harnesses this vibrational energy and redirects it back into the formation in the form of improved ROP, keeping our cutters sharper, for longer.

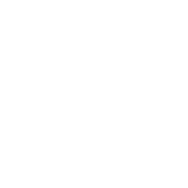

TECHNOLOGY

Cutters Positioned for Performance

Counterforce works by strategically positioning each cutting element for maximum cutting efficiency while also maintaining a continuous progression of work across the overall cutter layout. By leveraging alternating degrees of cutter orientation, Counterforce PDC bits slice the formation allowing the bit to grasp the bottom hole pattern, with the resultant traction limiting destructive and efficiency-robbing vibration. This improves tool face control while enhancing bit life and dull condition.

- High Performing Cutter Layouts

- Full Hole Coverage for Durability

- Engineered Tolerances & Force Tuned

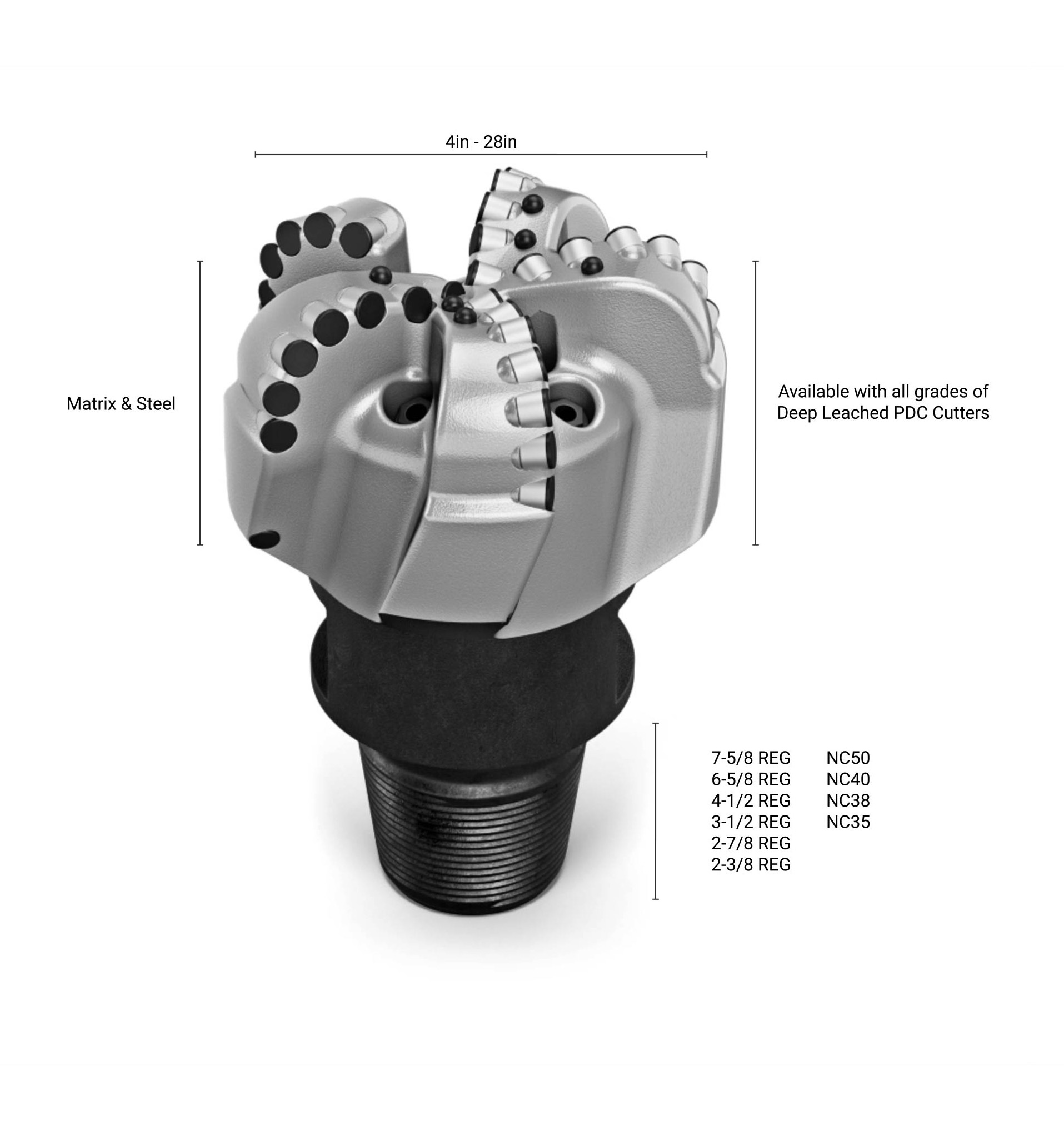

TECHNICAL SPECIFICATIONS

Size Range

4 in – 28 in

Body Materials

Matrix & Steel

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

3-1/2 REG, 4-1/2 REG, 6-7/8 REG, 7-7/8 REG

NC35, NC38. NC40, NC50

APPLICATIONS

Use in Every Basin, Every Section

Whether you’re drilling in the Bone Springs of the Permian Basin, or in the deep waters off the Gulf of Thailand, CounterForce technology solves the drilling dysfunction that commonly occurs from the effects of lateral vibration. See how we’ve engineered and applied CounterForce technology all over the world.

PERFORMANCE

Vibration Transformed into Speed

Drill faster, and remove more rock with less energy when the drilling force is working with you rather than against you. That’s what you get with CounterForce’s advanced cutter orientation that maximizes rock failure by redirecting energy back into the formation.