INTERBEDDED FORMATIONS

DISRUPT DYSFUNCTION

OVERVIEW

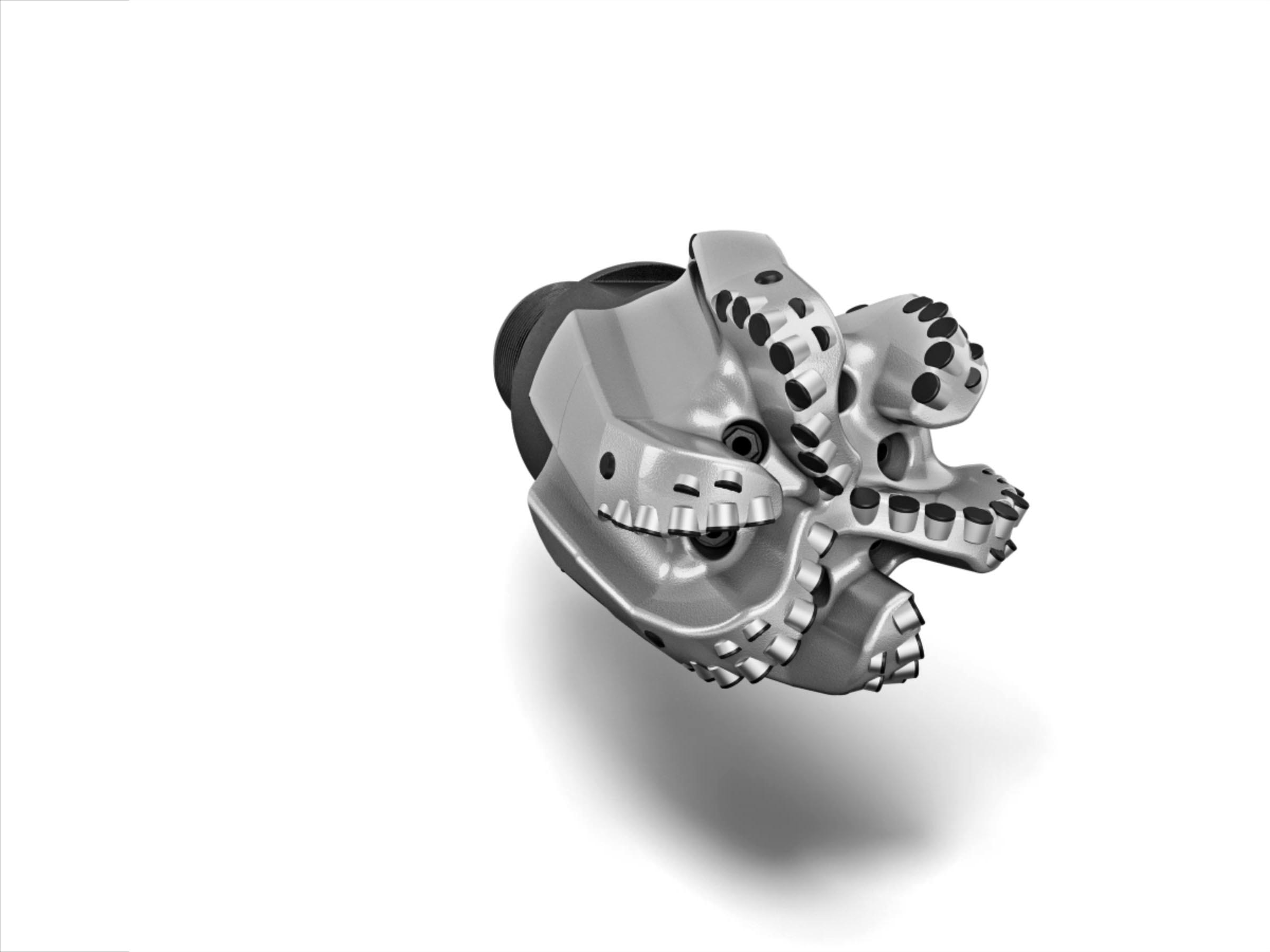

Disrupt Harsh Transitional Drilling

Many types of drilling dysfunction form cumulatively as the drill bit encounters continuous rock transitions. WaveCut® from Ulterra disrupts the standard rhythm of drilling to get ahead of vibration before it gets started. Launched in early 2022, WaveCut PDC bits stagger rock engagement blade-by-blade and cutter-by-cutter to break down the sources of vibration. Ulterra’s 5th patented cutting structure has yielded over 1500 runs and saved hundreds of tripping hours in the most challenging rock formations in North America.

- Dual phase, waved blade shape

- Staggered engagement creates unique cutter torque signatures

- Individual cutter torque prevents vibration harmonic accumulation

RETHINK ROCK ENGAGEMENT

Change the Pace of Engagement & Torque

Spikes in torque while drilling are common and can lead to big problems. Individually, they cause impact damage to the bit and equipment. What’s worse is when they collect over time, building up to large scale dysfunctions that threaten the entire BHA, causing damage and lost drilling performance and time.

WaveCut technology breaks apart torque while drilling, separating spikes into small, bite-size, chunks that are easily distributed. As each unique wave of cutters passes over the danger area, their rate of engagement is varied, and the resulting spike of the torque is drastically reduced. The result is smoother, more efficient drilling that increases ROP and extends bit life for longer drilling intervals.

TECHNOLOGY

Wave-Shaped Blades for Improve Drilling Efficiency

The unique design of WaveCut takes blade shape, cutter engagement, and drilling efficiency to the next level. Each blade is engineered according to the optimal position of the cutters on it and their resulting individual work prediction, which accounts for cutter location, position, and orientation to achieve maximum shearing efficiency. The result of which is expansive over the entire tool face, which elevates performance beyond current limiter thresholds.

- Dual-Phase Waveform Design

- Alternating Concave/Convex Curvature

- Simultaneous Disruption & Stabilization

- Hydraulic Optimization

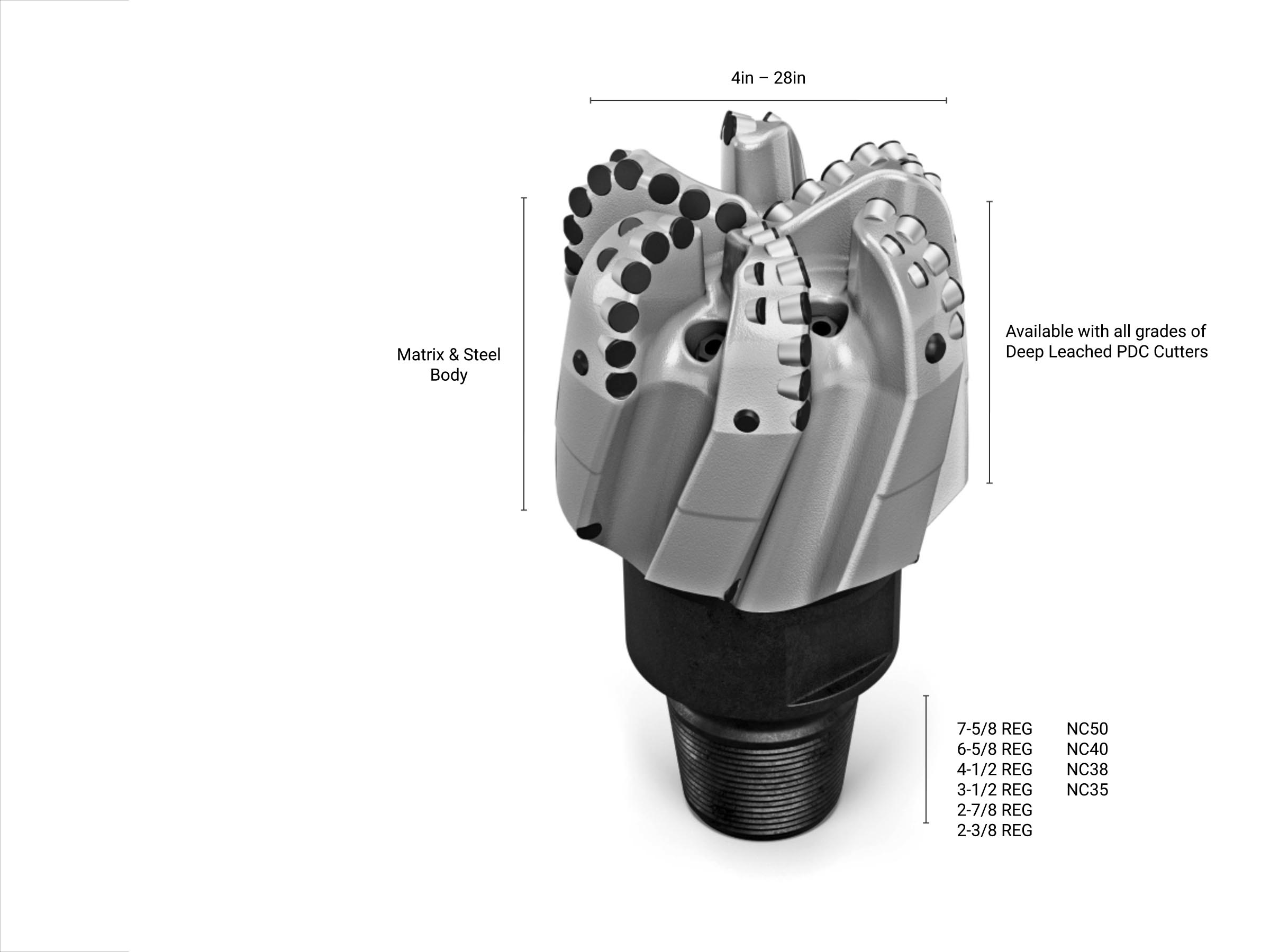

TECHNICAL SPECIFICATIONS

Size Range

6 in – 28 in (other sizes available upon request)

Body Materials

Matrix & Steel

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

3-1/2 REG, 4-1/2 REG, 6-5/8 REG, 7-5/8 REG

NC35, NC38, NC40, NC50

APPLICATIONS

North American Interbedded Rock

To date, WaveCut has made significant improvements for operators drilling vertical and intermediate formations in the Permian of New Mexico & West Texas, as well as deeper transitional drilling in Western Alberta, Canada.

Future promising applications include deeper curve/lateral applications where drilling efficiency is mandatory and MSE critical applications where every pound of weight on bit counts.

PERFORMANCE

Case Studies

WaveCut has demonstrated proven drilling efficiency in the applications it’s been run. From situations where vibration and dysfunction were reduced to raising the performance ceiling and founder’s point with the same weight on bit. WaveCut brings drilling efficiency that applies to multiple different objectives for drillers all over.