LONGER LASTING

BETTER PERFORMING

RESULTS DRIVEN DEVELOPMENT

OVERVIEW

The Leaching Edge of Cutter Technology

The Ulterra OMEGA® program is the combination of new product innovation with rapid iterative development. Drill, Evaluate, Optimize, Repeat. The only program of its kind, our OMEGA process delivers deep leached, latest-generation PDC cutters in the bits you need and the speed you need it.

Drill

We select the right Omega premium cutter for the job, based on the application and drilling objectives.

Evaluate

Omega engineers perform post-run analysis on every Omega run to evaluate cutter performance and discover opportunities for future improvement.

Optimize

We share this analysis with our Omega Partners, the world’s leading PDC suppliers, to improve our cutter technology.

Repeat

Once a new grade of cutter has been developed, and passes internal trials, we get it to the field in a paired test and continue the cycle of continuous improvement.

DEVELOPMENT PROCESS

A Perpetual Feedback Loop of Improvement

It starts and ends with communication. The first part of OMEGA is the development cycle that shares key application insights with Ulterra’s cutter development engineers. Our development and application teams work tirelessly with our suppliers and OMEGA Partners to deliver a constant stream of PDC diamond improvement. Daily communication with application engineers in the field creates a powerful feedback loop that leads to innovative insights in cutters. Our engineers quickly return performance analysis reports to initiate the next cycle of development in cutter technology.

The bottom line for OMEGA development is what matters most to you in the field — operating with the latest advancements in cutter technology.

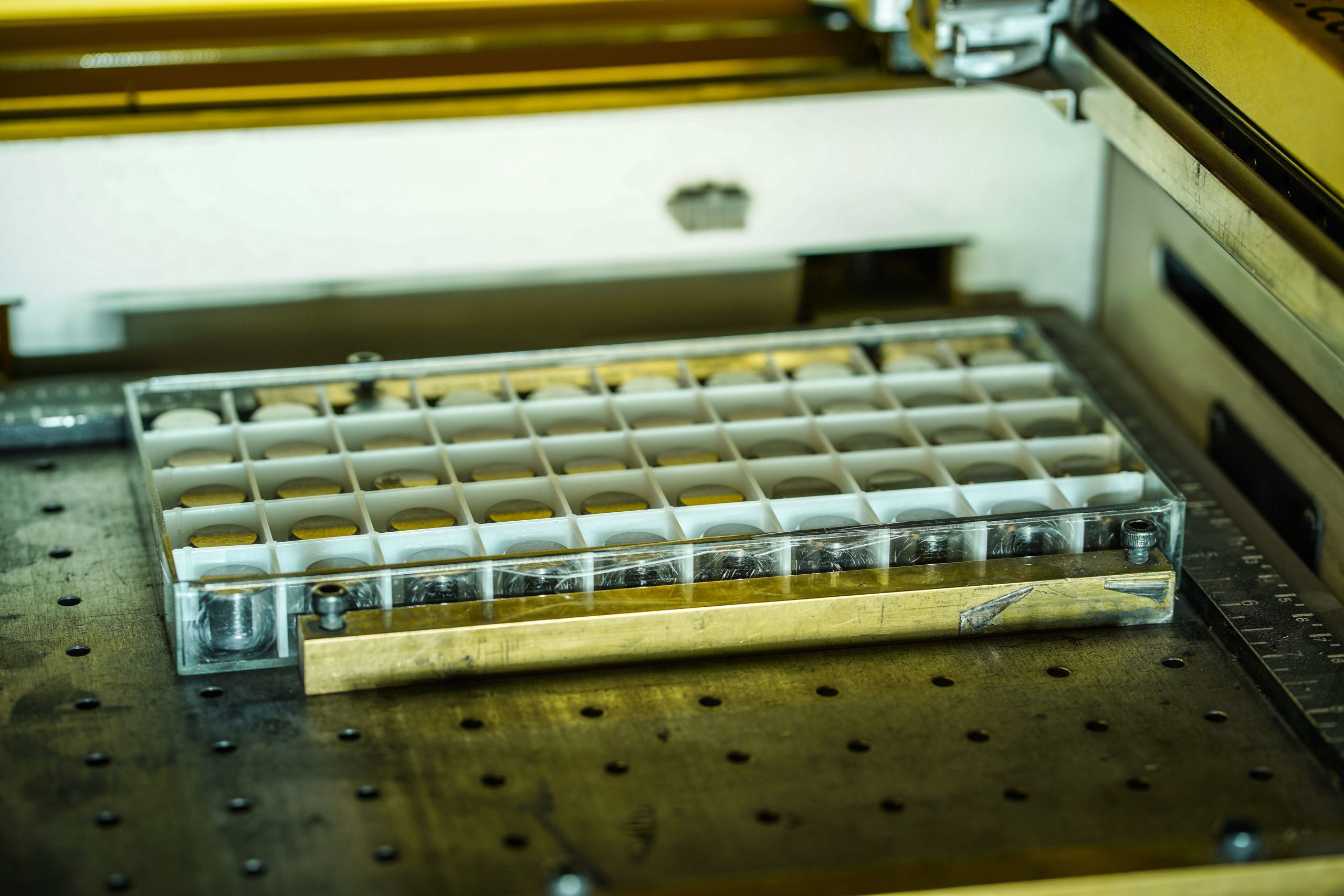

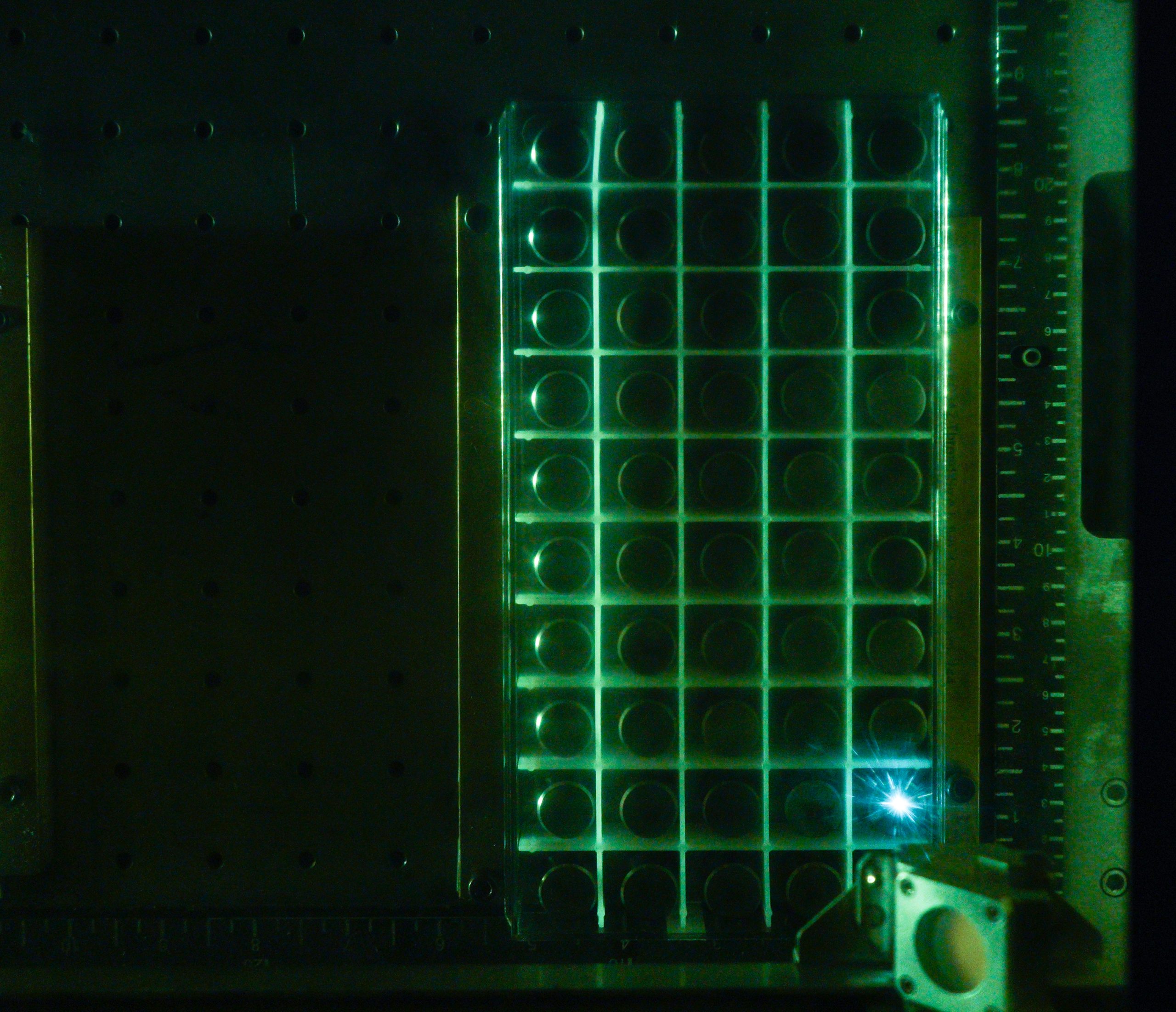

PRODUCT TECHNOLOGY

Dynamic OMEGA Cutters

Our OMEGA premium cutters are deep-leached, multi-modal diamond-grade cutters produced by the world’s leading PDC suppliers. We use real-world performance feedback to continuously improve the three most critical aspects of a cutter; it’s resistance to abrasion, impact, and thermal degradation.

Our aptitude for engineering the balance of diamond, substrate and leaching formulation of each cutter grade allows us to quickly match a product development with a target performance profile and bring that new technology to the field in a fully fit-for-purpose drill bit.

Diamond

Abrasive and impact resistance start here. We engineer our cutters using proprietary grain size distribution and processing techniques.

Substrate

We use advanced non-planar interfaces to balance internal stresses for maximum bonding strength, which improves overall cutter durability.

Leaching

You get game-changing performance with licensed deep leaching capabilities that match the leach depth and cutter grade to improve thermal stability. Keeping cutters sharper for longer drilling.

PARTNERSHIP

The World’s Leading Suppliers, Matched by Performance

OMEGA partners include the manufacturers of the top 90% of the premium PDC cutters sold across the globe. Each partner has dedicated engineering teams and production cells focused exclusively on Ulterra product development. The end result is that you promptly get the latest and greatest in cutter technology.

Ulterra is #1 in developing and delivering drilling technology to the Oil and Gas industry.

Sales Director for a Leading PDC Supplier