IMPROVED HYDRAULICS

UNLEASH PERFORMANCE

OVERVIEW

Unleash Your Speed™

Split Blade® from Ulterra is an evolution of PDC bit design and advanced hydraulics in drilling mechanics. Taking the industry by storm in 2018, Ulterra’s award-winning Split Blade PDC bits have been used in every major basin across the globe. In it’s first year, the patented blade, cutter, and nozzle configuration has yielded over 5000 runs, 30 million feet drilled, and saved thousands of drilling hours by offering improved evacuation resulting in longer cutter life. Split Blade technology has ushered in a new generation of high-performance drill bits for the Oil & Gas industry

- Double-barrel hydraulics

- Better formation contact distribution

- Greater cutter layout freedom

IMPROVED HYDRAULICS

Better Cuttings Evacuation

If you’re drilling, you’re creating cuttings. These cuttings can stagnate and collect around the cutters and within the junk slot of most bits, impeding evacuation and limiting not only the volume of rock that can be evacuated (a direct function of ROP), but also limiting your operating depth of cut. This directly impacts the performance of your bit and your BHA.

Ulterra’s Split Blade technology separates the flow channel of cuttings coming from the cone and shoulder of the bit. Isolating their flow paths improves their evacuation velocity. The result is a cleaner cone for higher maximum ROP and a cleaner shoulder for better durability into extended laterals.

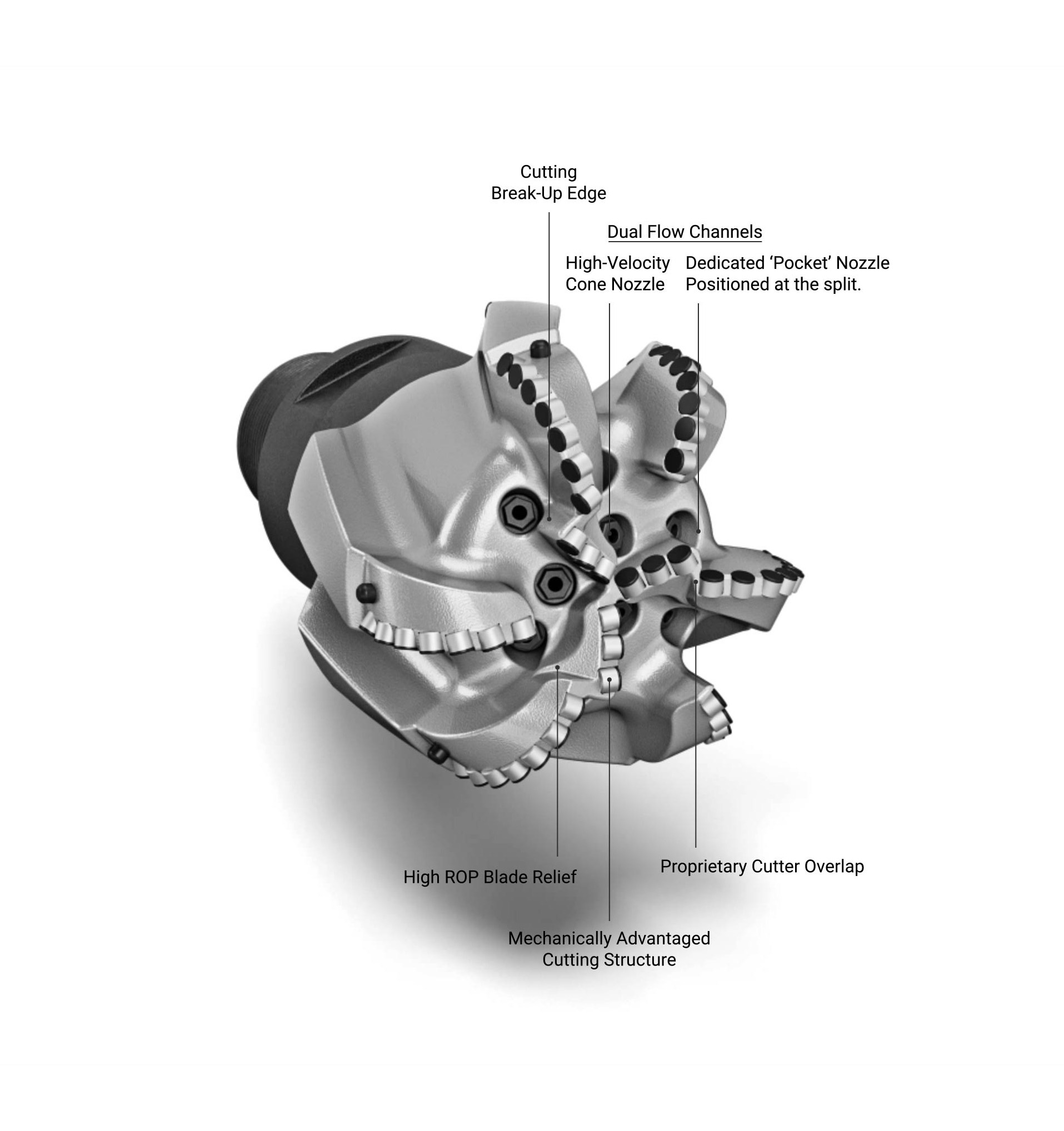

TECHNOLOGY

Different Design for a Different Level of Performance

The innovative design of SplitBlade looks different than traditional straight blade drill bits because it serves a purpose in changing performance. The primary blades are offset after the cone and the outer shoulders are rotated, creating double-barrel hydraulic channels that promote high speed cuttings evacuation and free up more area for the junk slot. In addition, the blades are engineered to exceed industry standards for strength and optimum depth of cut requirements

- Cleaner cutters improve cooling

- Cooler cutters are more durable

- Durable cutters have a higher sharpness interval

- All with better cuttings evacuation

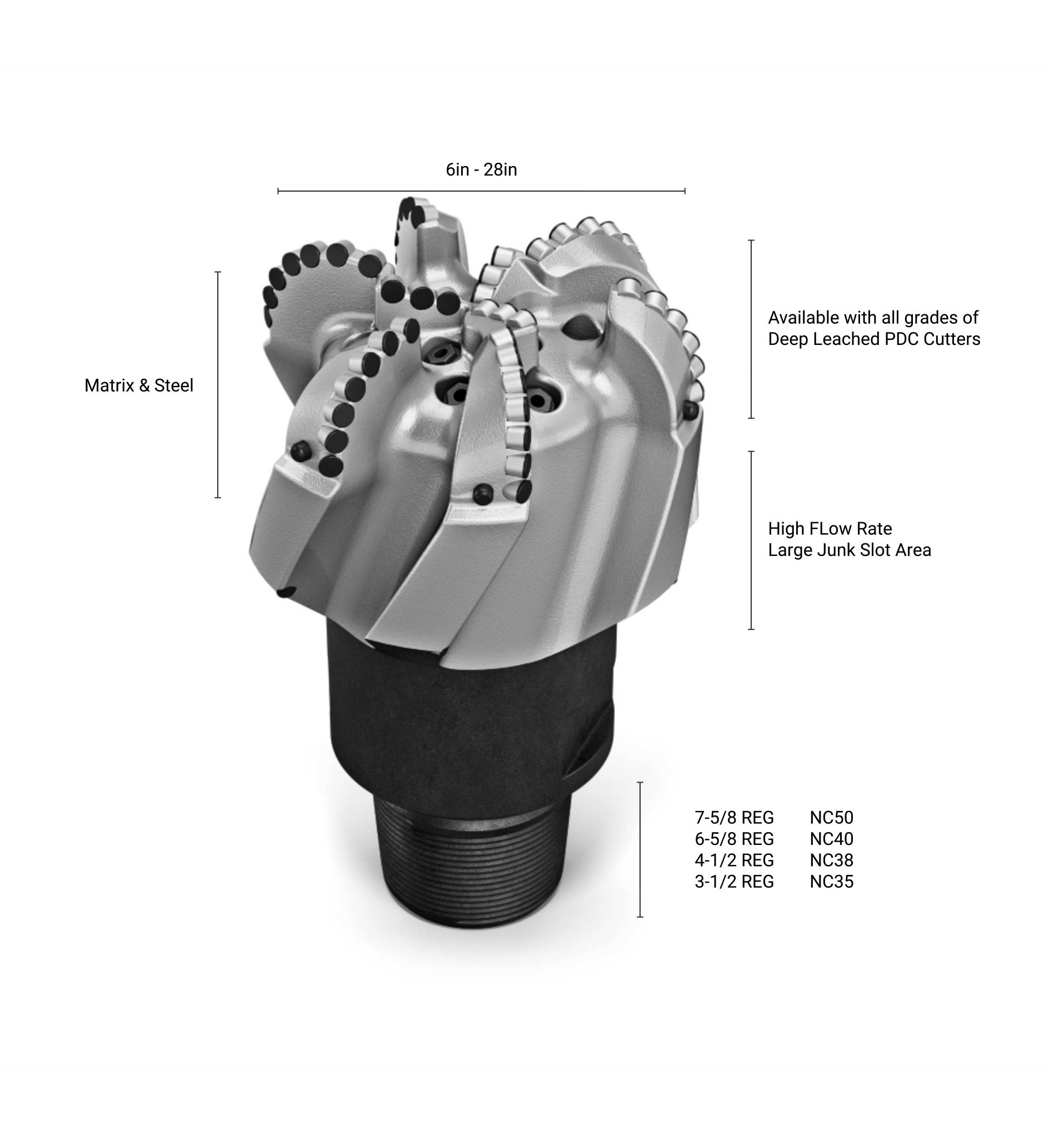

TECHNICAL SPECIFICATIONS

Size Range

6 in – 28 in (other sizes available upon request)

Body Materials

Matrix & Steel

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

3-1/2 REG, 4-1/2 REG, 6-5/8 REG, 7-5/8 REG

NC35, NC38, NC40, NC50

APPLICATIONS

Use in Every Basin, Every Section

Whether you’re drilling in the Bone Springs of the Permian Basin, or in the deep waters off the Gulf of Thailand, Split Blade technology improves the evacuation of cuttings, keeping the bit cleaner and unleashing your maximum drilling efficiency. See how we’ve engineered and applied Split Blade technology all over the world.

PERFORMANCE

A Clean Bit is a Faster Bit

Split Blade is designed specifically to evacuate cuttings quickly from the cone and shoulder of the bit, keeping cutters clear to maximize their cutting rate. The cleaner cone results in a higher maximum ROP and a cleaner shoulder for better durability and improved control into extended laterals.