FASTER PERFORMANCE

LONGER BIT LIFE

BETTER SAFETY

OVERVIEW

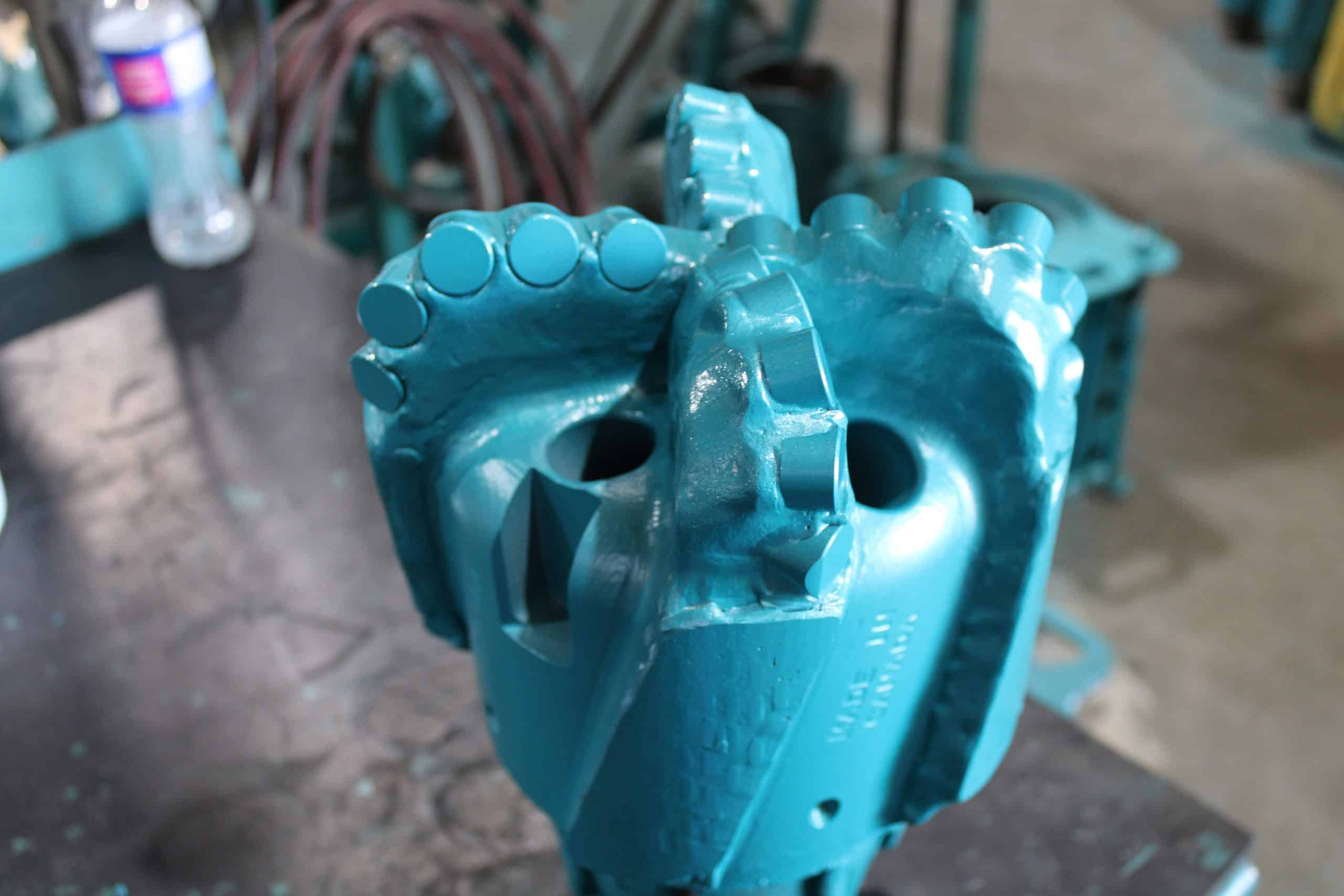

PDC Bits Are Built for Mining

Made in America: We manufacture Ulterra’s PDC drill bits domestically to bring you the next generation of mining technology. With their Polycrystalline Diamond Compact (PDC) cutters, PDC bits use torque to shear rock and drill further, faster, and smoother than roller cone bits. These bits reduce maintenance costs, improve safety on the job site, and save time.

Top 5 reasons to use PDC bits:

- 1. Increased safety from smoother drilling

- 2. Longer bit life

- 3. Increased ROP

- 4. Straighter holes

- 5. Better collaring

SAFETY

Safer Drilling from the Ground Up

Safety is the most important part of our PDC drill bits. The torque-driven drilling action that shears instead of crushes means less weight to accomplish more. Less weight means less potential energy within the system to impact performance. Finally, with no moving parts to fail, PDC bits last longer and reduce the number of bit swaps. You stay focused on drilling, not maintenance, from the safety of the driller’s cab.

SMOOTH DRILLING

More Drilling Feel, No Hassles

Drilling with an Ulterra PDC bit is smoother, cleaner, and more efficient than drilling with roller cone bits. Using torque instead of weight to shear rock smoothly and reduce all forms of vibration, these bits virtually eliminate rod rattle. Pairing our PDC bits with Ulterra’s SoftDrive™ drilling system further amplifies the vibration-reducing impact.

HIGH PERFORMANCE

Built for Higher Penetration Rates

Ulterra builds our mining bits for speed and durability. We use advanced wear and fluid simulation software to engineer each bit’s cutting structure for maximum performance in the target application. We’ve proven in a head-to-head comparison that with Ulterra bits, you’ll drill more feet faster while saving costs.

How it Cuts

Shear

Lifespan

Over 15 km

Average Speed

200 m/hr

Lost Cone Risk

No

Vibration

Low

BETTER COLLARING

A Higher Quality Hole for Consistent Blasting

PDC bits drill less violently and more precisely for better hole quality. For blastholes, this directly translates into higher-quality collaring for the mining industry, which makes blasting more predictable and safer. The blasted rock is also more uniform, reducing the overall time spent working to clear a blasted bench.

DRILLING SCIENCE

Roller-Cone vs. PDC

PDC SHEARING

Ulterra PDC bits use a shearing motion to cut the rock instead of crushing it. This means higher drilling efficiency in all kinds of rock that traditional roller cone bits can’t match. Using shear force to cut rock, you can drill twice as fast and twice as smooth while applying the same weight.

ROLLER CONE CRUSHING

Traditional roller cone or tricone bits drill with a crushing motion to repeatedly pulverize rock until the cuttings are small enough to travel up the annulus. This method for drilling has high requirements on WOB and generates violent vibrations that ricochet up the drill string due to the larger load placed on the bit while drilling.

CUSTOMER SERVICE

More than a Provider. A Drilling Partner.

Ulterra builds our reputation on consistency, performance, and trust. We lead the industry in responsiveness and customer service because we understand and provide the level of support required to get the job done. With Ulterra, you get more than a drilling bit. You get a drilling team.