EXTREME PARAMETERS

MAXIMUM DURABILITY

OVERVIEW

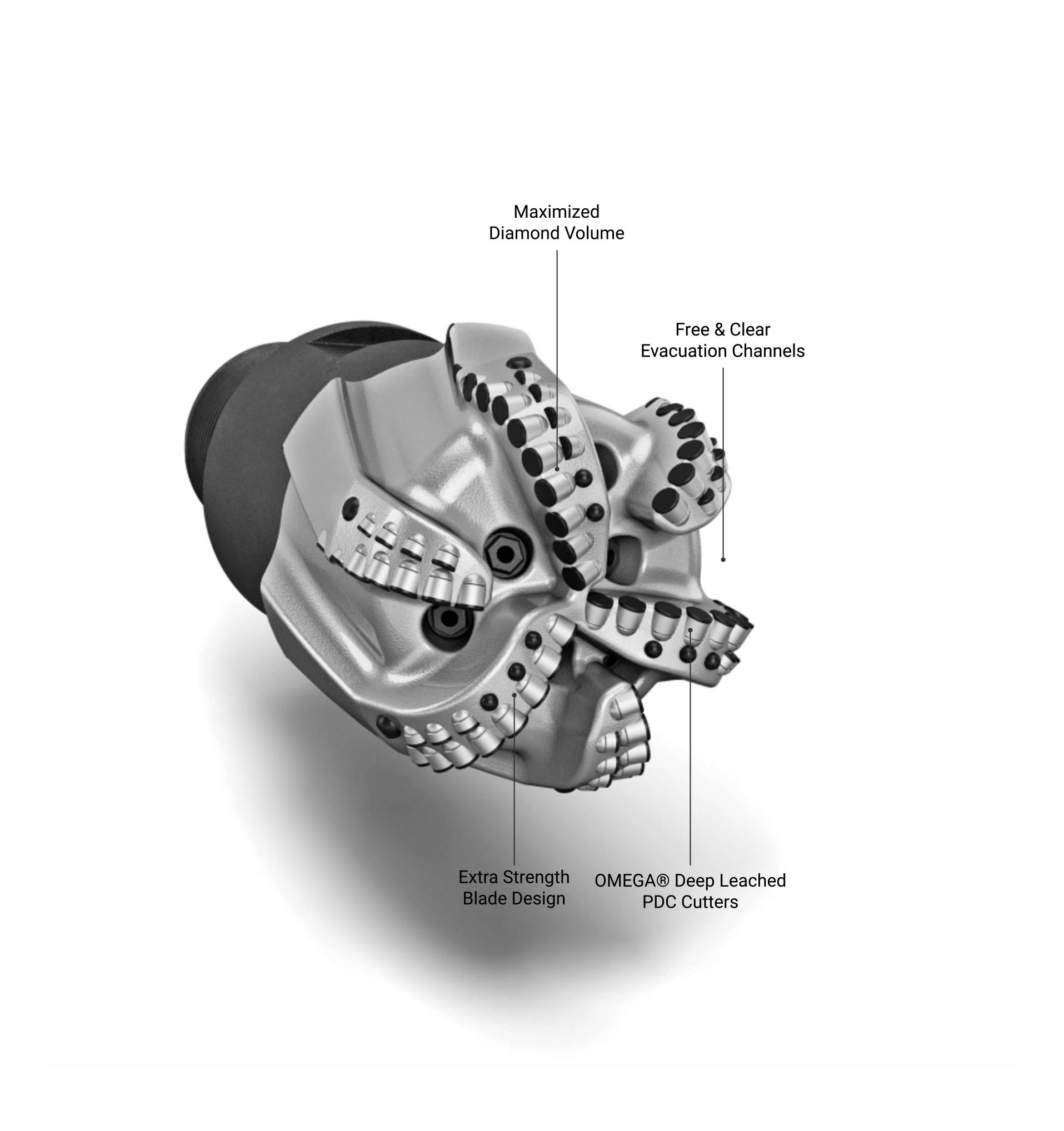

XP Is Built Tough

Hard rock? Transition zones? Highly interbedded lithologies? XP has it covered. Whatever drilling challenges you might be facing, Ulterra has the knowledge and expertise to help you break through and drill with maximum efficiency. Our XP bits are specifically designed for each application and are paired with the latest premium PDC cutter technology.

- Over-engineered bit body to ensure structural integrity

- Cutter positioning and face modeling to reduce tangential overload

- Application-specific premium PDC cutters

- Force-balanced for maximum stability

DRILLING

For Your Toughest Drilling Challenges

Ulterra’s range of XP bits is designed to meet the most challenging hard-rock applications. We build the XP series on a bit body created to ensure structural integrity under extreme drilling conditions. This level of design enables the bit to withstand challenges that place a higher level of stress on the bit, including greater weight-on-bit (WOB), without sacrificing ROP. XP bits deliver the best possible performance, even in the most difficult drilling environments.

TECHNOLOGY

Performance Through Durability

Ulterra’s ongoing materials and manufacturing research means that XP PDC bits will always use the latest technology to help unleash maximum drilling performance while lasting longer down hole. Longer-lasting performance means reliability, and a more reliable bit is one you can trust, even in the most demanding applications.

- High Performing Cutter Layouts

- Full Hole Coverage for Durability

- Engineered Tolerances & Force Tuned

TECHNICAL SPECIFICATIONS

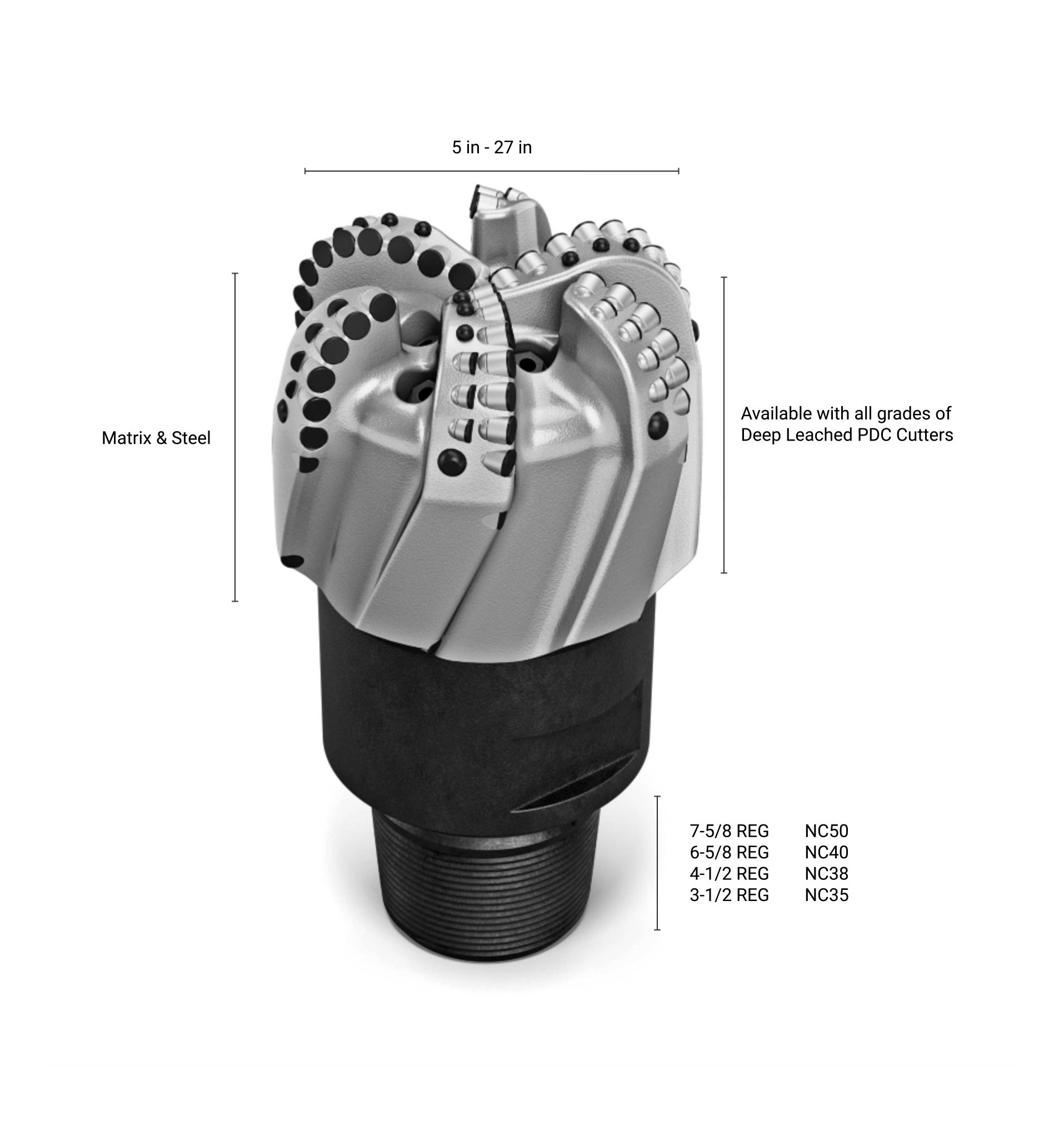

Size Range

5 in – 27 in

Body Materials

Matrix & Steel

Cutter Grades

Available for all grades of Deep Leached Cutters

Connections

3-1/2 REG, 4-1/2 REG, 6-7/8 REG, 7-7/8 REG

NC35, NC38, NC40, NC50

PERFORMANCE

Optimized Performance with the Highest Durability

XP bits are the most durable PDC drill bits on the market, and we build them with the highest-quality design, materials, and manufacturing. To build in top performance, Ulterra focuses on elements such as building the bit body stronger than necessary to keep its structural integrity and positioning the cutters to reduce tangential overload.

Ulterra optimizes our XP bits for each application and pairs them with the latest application-specific premium PDC cutters. Our rapid design and prototyping process means that we optimize each design quickly, enabling operators to improve drilling performance from well to well. We manufacture and engineer our XP bits to make sure they never limit performance.